In modern engineering, industrial efficiency and precision are still very important. Controlling motion is key to getting great performance. To make sure that all of the pieces of a complicated system operate together flawlessly, electrical instruments are utilized. One of these crucial tools is motor controllers.

They control motors with incredible accuracy. Putting these controls together makes it easy to speed up, slow down, and change direction, which helps everyone work better.

The role of motor controllers is incredibly crucial for a lot of things, such as robotics, automated manufacturing, and equipment that need to be very accurate. This article speaks about how significant these devices are, what their major benefits and purposes are, and how crucial it is to cooperate with well-known energy companies to keep things going smoothly.

What are Motor Controllers?

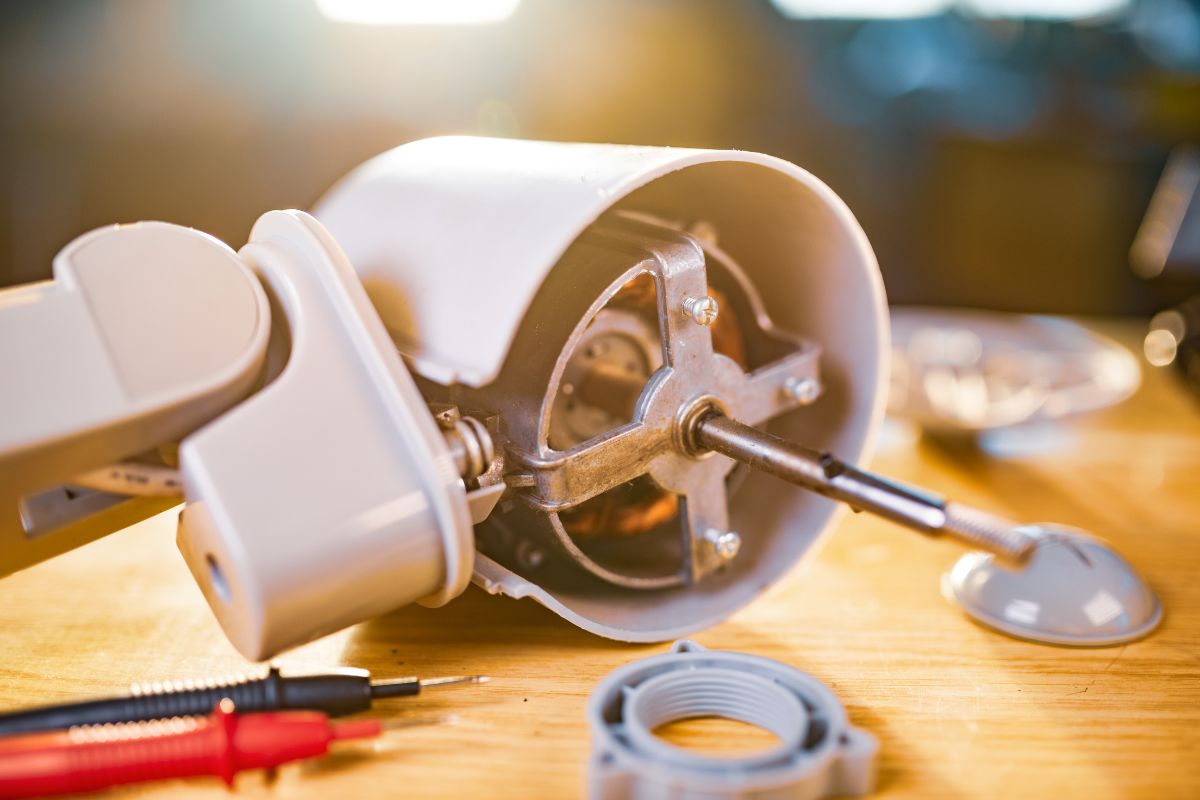

Motor controllers are special devices that are developed to regulate and manage how electric motors perform. To make sure everything functions smoothly no matter how much weight is on it, they utilize complicated systems to control speed, torque, and direction.

These gadgets include sensors and powerful control algorithms that help them react to input in real time, which cuts down on wear and tear and makes them work better. They may be utilized in a lot of different areas, from medical equipment that has to be highly accurate to high-speed automation systems.

Motor controllers are a critical aspect of gaining accurate control in challenging industrial situations since they are made to endure and operate effectively. These tools are designed to work well even in rough places. Adding them to systems not only makes them simpler to keep running, but it also helps them run more smoothly.

The adoption of these controllers has led to significant advancements in industrial automation, allowing companies to reduce downtime and enhance product quality.

Key Functions and Applications

- Accurate Speed Regulation: Motor controllers enable you modify the speed of the motor to fit the demands of the operation. This makes sure that automated production lines perform at their best.

- Enhanced Directional Control: These devices, like motor controllers, provide you reliable directional control that assists with hard jobs and maintains the system steady.

Precision Control and Enhanced Performance

What makes industrial processes operate is still accuracy. Motor controllers have modified how systems maintain their speed and movement right. By carefully managing how quickly and slow they travel, these technologies maintain operations stable and efficient.

They help equipment last longer by giving you precise control, which reduces mechanical strain and energy waste. This degree of control is needed in situations where even little modifications might cause difficulties with operations.

They work better and provide better results because they can adapt to changing load conditions. Because of this, firms spend less on upkeep and get more done overall.

Integration into Industrial Systems

To add new electrical instruments to old systems, you need to plan carefully and make sure they will work together. Engineers need to think about a number of things, such as the system load, the environment in which it will be used, and how it will grow in the future.

Motor controllers are particularly vital for making sure that all the pieces of a networked system operate effectively together. They can link to digital control networks, which lets you keep an eye on things from a distance and make rapid modifications, which cuts down on operational difficulties.

For the optimum results, you need to utilize a thorough approach that involves a lot of testing, calibration, and regular monitoring. By tailoring integration solutions to meet the needs of each application, businesses may make their systems more reliable and their operations run more smoothly.

Real-time Monitoring and Digital Integration

Modern factories demand quick management and frequent data. You can now monitor and diagnose electrical components like motor controllers from a distance since they can talk to each other digitally.

This link makes it simpler to make fast modifications, which minimizes the chance of system failures and makes everything safer. With continual feedback, operators can quickly spot issues and rectify them, which saves downtime from being too costly.

These advanced controllers and digital networks perform so effectively together that they urge a proactive maintenance strategy. This not only keeps everything running, but it also saves a lot of money in the long run.

Advancements and Emerging Trends

The way firms function will continue to alter because of new control technologies. These electrical instruments are becoming increasingly more precise and sensitive thanks to new sensor technology and algorithm design.

The continued work on motor controllers is making it feasible to employ AI and machine learning to manage systems. This will make it possible to do maintenance ahead of time and change the performance settings as needed.

Even while the industry is currently focused on safety and reliability, emerging trends suggest that the next generation of these devices will be far more efficient and adaptable than the ones we have now. It will help industrial systems remain competitive and endure longer in a market that changes fast. These changes are meant to raise the bar for businesses across the globe.

Strategic Partnership for Sustainable Growth

The creation of motor controllers has transformed what businesses look for in terms of precision and performance. They are currently key instruments in modern manufacturing and automation since they can provide feedback in real time and function well with digital systems.

The strategic use of new technology will be highly vital for firms that want to boost production and cut down on downtime. The future of industrial control lies clearly in the continued improvement of these systems, which improve productivity and make them last longer.

When you work with well-known energy firms, you can be confident that your systems have high-quality motor controllers and other parts, which makes them more dependable overall.