An actuator is a machine part that is used for the movement of an instrument and controlling an instrument, sometimes by opening and closing of a valve. It is also known as a mover.

An actuator requires a control signal to move accordingly as per the suggested signals. The control signal is of electric voltage or flow pneumatic, or even human power. Its fundamental vitality source might be an electric flow, water-powered liquid weight, or pneumatic weight.

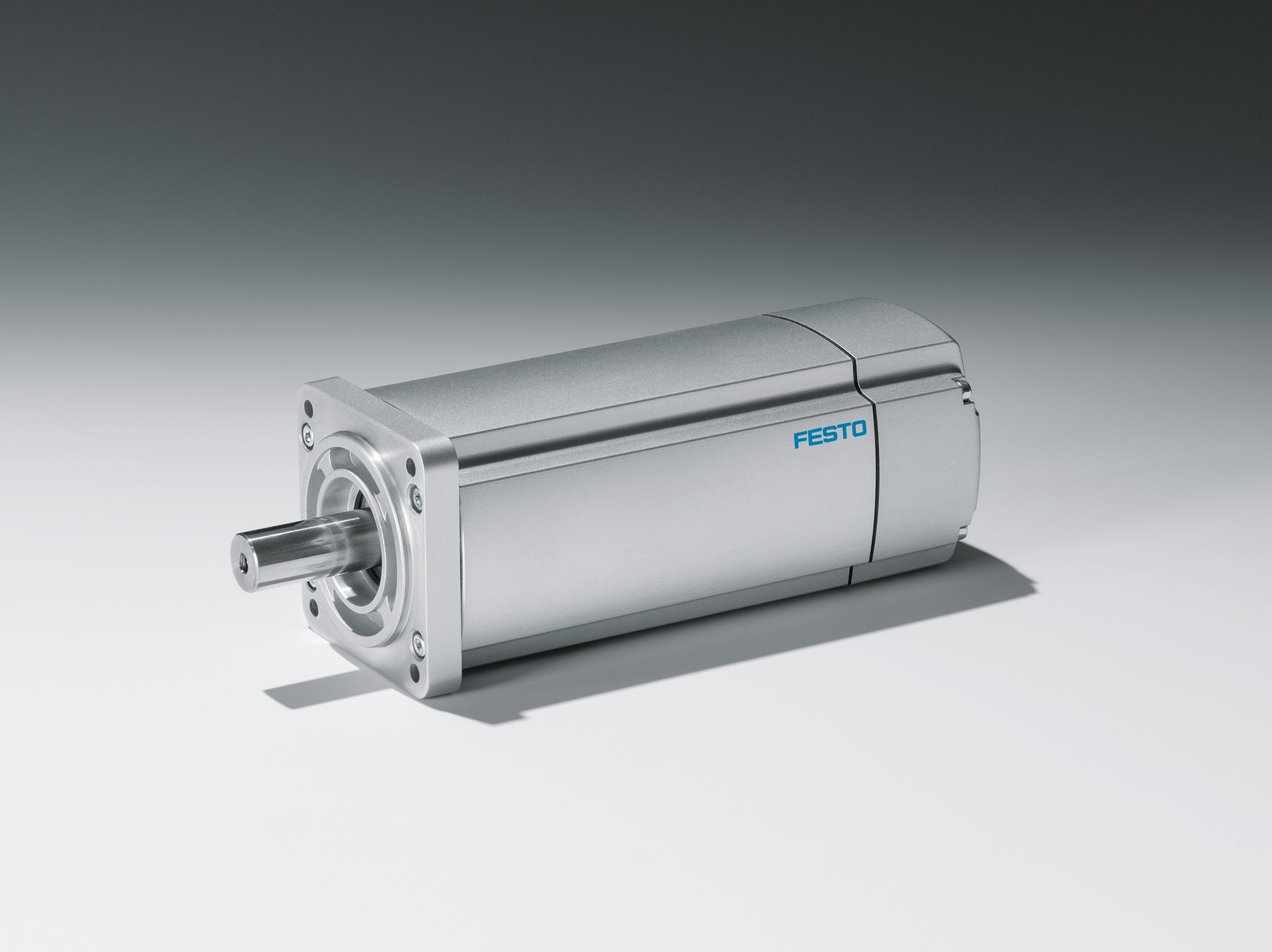

At the point when it gets a control signal, an actuator reacts by changing over the sign’s vitality into mechanical movement. A Festo distributor in India provides the best quality of actuators.

Actuators might be controlled by electric flow, water driven liquid or pneumatic weight. In inserted frameworks, the control signal originates from a microcontroller modified by programming. Gadget drivers send a contribution to a fringe gadget, for example, a printer.

While actuators regularly give roundabout movement, they can change over round movement into straight movement by means of screws and haggle gadgets. A case of the last is a rack and pinion framework. The actuator’s movement can be in basically any structure, for example, blocking, cinching or catapulting.

An actuator is a motor that takes a shot at rotor and stator congregations. These are regularly known as the essential and optional windings inside the engine. Voltage is applied to the stator get together – the essential winding – which brings about prompting the progression of current to the rotor get together, or the auxiliary winding.

The collaboration of these two makes an attractive field that outcomes moving. There are two kinds of engines: AC engines, which generally move at a consistent speed; and DC engines, which move at variable paces.

Types of actuators according to power –

Hydraulic actuator

In a pressure-driven actuator, a chamber or liquid-based engine utilizes the intensity of hydrodynamics to make mechanical activity. The movement can be either straight, pivoting or swaying. The way that fluids don’t pack well makes a pressure-driven actuator incredible. The pressure-driven power can be applied to one of the two sides of a cylinder.

Pneumatic actuator

With a pneumatic actuator, a vacuum or compacted air is utilized to make vitality enthusiastically. They are useful for making a huge direct or turning movement with a modest quantity of weight. Due to the utilization of high strain to control them, pneumatic actuators react rapidly and are useful for halting and beginning as are useful for fundamental motor controls.

Electrical actuator

The most widely recognized sort of actuator is an electrical one that can take electrical vitality from DC or AC and transform it into mechanical vitality. Since this is a clean and effectively accessible innovation, electrical actuators are famous for some sorts of businesses and things like multi-turn valves.

Warm (Magnetic) actuator

Another name for warm actuators is “shape memory amalgams” (SMMs) in light of the fact that these kinds of actuators use SMMs to make high power thickness vitality for business applications. The benefits of warm actuators are that they are financially savvy, little and lightweight.

Mechanical actuator

Utilizing pulleys, apparatuses, rails, and chains, a mechanical actuator changes over the pivoting movement of physical items into direct movement. One regular model is rack and pinion guiding frameworks.