Nuts, bolts, and rivets are essential elements that generate the mechanism to move devices with joints and different parts. These fastening parts require another ingredient to protect their surface from abrasions when creating friction in the movement. A washer is such a vital component that allows these fastened joints to function without damaging them in the system. You might know many things about screws and nuts, but it is important to use the correct washer for a joint. Since washers come in various types and characteristics, you should get familiar with some common features to choose the right one.

Material

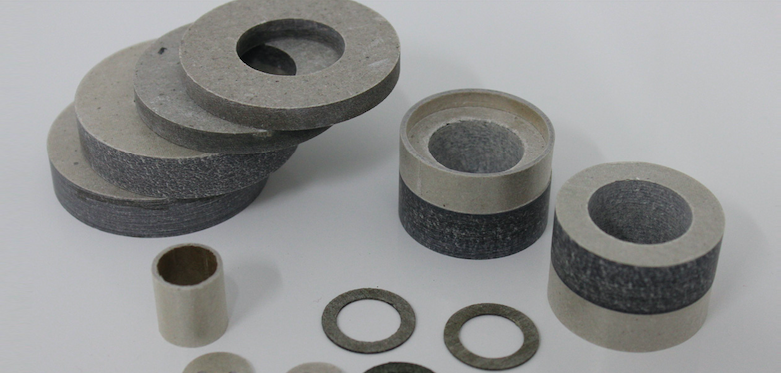

The physical properties of the washer rely on the type of material that builds the component. A washer can be in the form of metallic and nonmetallic material. The material determines the capacity and particular treatment when applying on a specific assembly task. Some applications require a washer to withstand the pressure, but others need to ensure that the washer protects the device from extremely high temperatures. A spring steel washer can resist high pressure while mica insulating washers can withstand temperatures ranging from 130°C to 1000°C. Low and medium carbon steel, stainless steel, copper, phosphor bronze, titanium, and aluminum are common metallic washers. Meanwhile, mica, rubber, nylon, and phenolic materials are the most preferred non-metallic washers.

Style

If you look at the list of industrial washers, you might shock to find out that most of them are similar in a way with a small change in the structure. Depending on the type of material, OEMs decide the style of washers. Flat, shoulder, tab, lock, countersunk, and spring washers are common types that are popular in the industry. Some of them also have hexagonal shapes for internal and external joint assembly. Shoulder washers are made of non-metal material that has low conductivity, and they are ideal for the electronic equipment industry. Tab washers are components that can hold nuts and bolts in an extreme environment. They are effective in locking devices in applications that involve vibrations.

Corrosion resistance

The aim of using a washer is to avoid equipment damage due to the friction that can cause corrosions. Since natural elements have a low capability to resist heat, moisture, and pressure, some washers have coated layers to protect their structure. Oxidizing, phosphating, electroplating, and metal spraying are some common methods to improve the strength of the washer material. Metals such as nickel, zinc, cadmium, and aluminum are widely used as a coating material for metal washers. While a mixture of zinc and phosphate with protective oil can resist corrosion, while nickel and phosphor mixed coating layer can prevent chemical reactions.

When you look for a washer for assembly, you should consider the type of applications and the risk factors of the environment. The OEM industry has a standard size, thickness, and material for specific purposes. Washer manufacturers establish a set of applications for different washers to help engineers find the right product.